iPhone 6S Leather case Development #3

Hello, this is ENZZO.

It’s been a little while, how are you guys doing?

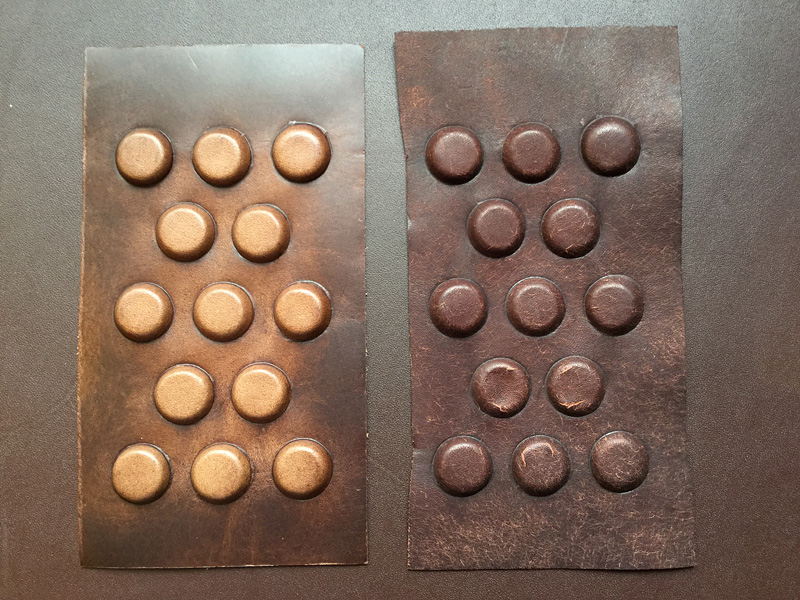

I told you about the first sample last time. And this time we got a second sample based on a more elaborate wooden mold. The leather we used for the first sample was the Ulysses’s standard Italian “pueblo” leather from BADALASSI CARLO, but this time for the second sample, we tried the “MARREMMA” leather, from another renown Italian leather factory Conceria Walpier, which is like pueblo the high-quality vegetable tanned Italian leather made in Toscana.,

But on the contrary to our high expectation, it didn’t come out to be so sophisticated.

After the numerous discussions among our staff, we have come to conclusion that the indent design is not so good for the first place and we decided to change the design to the opposite; we use protrusions. We can just use the same wooden mold to press the leather from back of it.

When we tried this with “MARREMMA” leather, we can have firm protrusions but it is too much and looks like Lego block.

We also tried “pueblo” leather and this time the part of the protrusions didn’t so stand out since it didn’t turn out to be white or so steep. Instead, we found some cracks; when pressing by the wooden mold, the leather which originally has a damage processing on the surface was stretched and caused some cracks. So I decided to reconsider the shape and the size of the protrusion and the space between them for the third sample, and we will have to renew and make over a new wooden mold again.

By the way, problem of what to do with the back of the protrusions was solved by putting the hard foaming urethane in the hollow. Now we are ready to make the third sample in this direction.

See ya.